Types:KCMA-9P1WB KCM-9P1WB KCME-9P1WB KCMF-9P1WB KCMG-9P1WB KCMD-9P1WB KCMA-9P2WB KCM-9P2WB KCME-9P2WB KCMF-9P2WB KCMG-9P2WB KCMD-9P2WB

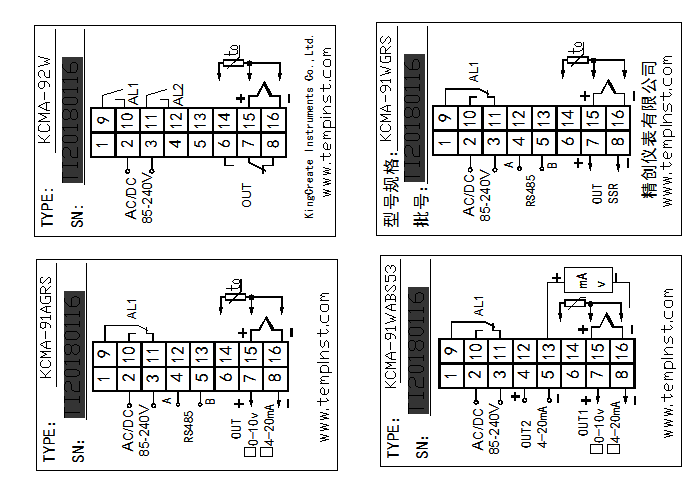

Terminal Arrangement:

| Register Address | Code | Name | Manual | Setting range | Ex-Factory |

|---|---|---|---|---|---|

| 0x00 | SP | Setting value | When run = 0, no program segment controlling. | Determined by P-SL P-SH | 100 |

| The main parameters (PART 1). Basic Setting Level | |||||

| 0x01 | AL-1 | Alarm 1 | Please refer to ALP for the alarm mode suitable. Alarming when the program sections is breaking up. |

Determined by P-SL P-SH | - |

| 0x02 | AL-2 | Alarm 2 | - | ||

| 0x03 | Pb | PV Bias | The value set in the PV bias is added to the actual input value to correct the input value. | ±20.0 | 0 |

| 0x04 | KP | Proportional band | Set when PI or PID control is performance. For heating / cooling PID action. When P=0,the meter is ON/OFF control |

0-3000 | 100 |

| 0x05 | KI | Integral time | Eliminates offset occurring in proportional control. | 0~3000 | 500 |

| 0x06 | KD | Derivative time | Prevents overshoot and/or undershoot caused by integral action effect.. | 0~2000S | 100S |

| 0x06 | KT | PID control cycle. | Control response time | 2~120 | 20 |

| 0x07 | FC | Digital Filter | This is a 1st-order lay filter by software prepared in order to reduce fluctuations of measured value (PV) by noise. | 0~50 | 20 |

| 0x08 | Hy | Differential gap | When the control is ON/OFF control(P=0) Relay contact may repeat its turning ON and OFF due to input fluctuation if measured value (PV) is near the alarm set value.the differential gap setting can prevent the relay contact from ON or OFF repetition. |

0.1~50.0 | 0.5 |

| 0x09 | dp | Decimal point position selection | Set the position of the decimal point for the measured value to be displayed. | 0~1 | 0 |

| 0x0A | outH | Output limiter high | Output limiter low to 200 | 200 | |

| 0x0B | outL | Output limiter low | 0 to Output limiter high | 0 | |

| 0x0C | AT | Autotuning (AT) with learning function | 1: Autotuning (AT) with learning start 0: Autotuning (AT) with learning stop Turns OFF automatically when the AT with learning function is completed. |

0~1 | 0 |

| 0x0D | LocK | Set data lock | LOCK=0, Set value (SV) and parameter can be set. LOCK=1,Only set value (SV) can be set. LOCK>1, Set value (SV) and parameter cannot be set. |

0~50 | 0 |

| 0x0E | ts | Input type1 | Cu50(–50.0~150.0℃); Pt100 (–199.9~600.0℃; ) K( -30.0~1300℃); E( -30.0~700.0℃); J (-30.0~900.0℃); T( -199.9~400.0℃); S( -30~1600℃); |

__ | K |

| 0x0F | Input type2 | 0~5V/0~10mA; 1~5V/4~20mA; |

__ | 4-20mA | |

| 0x10 | OP-A | Control output | 0:no output 1:Relay output 2:Voltage output (for driving SSR) 3:Zero-cross output(for driving Triac) 4:PID linear current output(4-20mA /0-10v) (A single functional) |

0~7 | READ ONLY |

| 0x11 | OP-B | AUX output Opt. | 0:no output; 1:RS232 or RS485; 2:contact the micro-printer; ‘ 3:transmitter 0~10mA 4:transmitter4~20mA |

0~4 | READ ONLY |

| 0x12 | ALP | Alarm type | 0: Alarm function OFF; ‘1’ Process high alarm; ‘2’ Process low alarm; ‘3’Process high and low alarm.(H1 and L2) ‘4’ Deviation High alarm ; ‘5 Deviation low alarm; ‘6’Deviation High and Low alarm..(H1 and L2) ‘7’ Deviation high/low alarm; ‘8 Band alarm. |

0~10 | According to the request |

| 0x13 | COOL | System function Opt. | ‘0’:reverse control(heating) ‘1’:positive control(cooling) |

0~1 | 0 |

| 0x14 | P-SH | Range high | The control is displayed after the Input type and Input range. | P-SL~9999 |

1300 |

| 0x15 | P-SL | Range low | -1999~P-SH | 0 | |

| 0x16 | Add | Address |

Communication address can be set from 0 to 255 | 0-255 | 1 |

| 0x17 | Baud | Communication speed | 1200; 2400; 4800; 9600; | ____ | 9600 |

| 0x18 | m-A | Manual output | |||

| Partial parameter of Program control (PART 2) Program Setting Level | |||||

| 0x19 | SEC | Set time unit | 0:minute, 1:second. | 0~1 | 0 |

| 0x1A | LOOP | Cycles | 0:Rest when program ended.. 1:Looping as a cycle. | 0~1 | 1 |

| 0x1B | PED | Power failure | 0:The Data was preserved when Power Down, and you need manual operation(press the key▲for 3 seconds)with the restoration; 1:No Preserving Data when power down, you need manual operation(press the key▲for 3 seconds)to Segment 1; 2:Data Preserved and automatic with the restorations, 3:No Preserving and it will return segment 1 with the restoration automatic. |

0~3 | |

| 0x1C | AL_P | Soak Band(Wait zone) |

The A-T lamp flash if the deviation absolute value[Measured value (PV) − Set value (SV)] is less than or greater than the AL_P set value to the control stop the timing. When Measured value (PV) does not follow the progress of the program (when difference between PV and SV remains) during the Program control operation, the program will be on standby state at Segment time end point until the Measured value (PV) reaches the Wait zone. |

0~100.0 | 10.0 |

| 0x1D | run | Program control mode setting | ‘0’stop:you can Press the▲key, modify SP values. Without Program segment control. ‘1’Rest:Rest when Program control was ended. ‘2’pause: Run with the current set value, and pause with no timing; ‘3’run:Program control runing |

0~3 | 0 |

| 0x1E | Pro | Program segmentation | Skip a random segment. Running time TE to reset at time | 0~64 | 0 |

| 0x1F | TE | Run time | The run time of nonce segment(only read) | ≤setting time of this section, the unit is minute | READ ONLY |

| 0x20 | r1 | Ramp Time 1 | The unit is min. (End with the previous segment when r=0. Ignored the Segment and Skip to next segment when r=2000) |

0-2000 min | - |

| 0x21 | t1 | Soak Time 1 | Soaking time of Platform 1, the Segment will be skipped to next section when the time is 0. | 0~9999 minute |

- |

| 0x22 | C1 | Segment 1 Set value | The first Constant temperature Soak segment. | Determined by P-SL P-SH |

- |

| ---- | |||||

| 0x7D | r32 | Ramp Time 32 | The same as above | ___ | |

| 0x7E | t32 | Soak Time 32 | The same as above | ___ | |

| 0x7F | C32 | Segment 32 Set value | The same as above | ___ | |